Let's face it: You or HVAC Comfort Consultants on your staff have a lot to remember when compiling a proposal for a homeowner. Every part and labor hour must be accounted for precisely — at least if you want to hit your profit margin targets! It's a difficult task for the following reasons:

- Unfortunately, visiting customers' homes can involve many noisy distractions that make it hard to gather all the details needed for the proposal with complete accuracy and within one visit.

- There are many variables necessary for an accurate quote, and sometimes a few details are missed that later have an impact on the job's profitability.

- Different sales team members may gather information for their quotes differently for larger HVAC contractors, leading some jobs to be more profitable than others.

What if you could automate the routine tasks your Comfort Consultants typically handle? Install Manager Pro ensures that your sales team never misses a beat — or any pertinent detail — when it comes to quoting a job. It's like having an experienced Install Manager on-site at every estimate, ensuring the most complete, accurate data possible.

Simply put, it's a process that relies too much on memory and suffers from too much variability from quote to quote and team member to team member.

How do you prevent job rollovers, part runs, and callbacks? How do you ensure an accurate labor hour estimate for every job quoted? How do you manage risk effectively? Consider three areas where Install Manager Pro helps you get it right the first time and protect your company's profits:

- Accurate bill of materials

Challenge: The bill of materials outlines each component you will need to complete a new HVAC installation. But what happens if your consultant forgets to include a part when compiling the HVAC proposal? Here's how one missing part can trigger an unfortunate chain of events:

- Parts/equipment not billed to the customer: Since the customer has already agreed to the estimate, you are responsible for covering the cost of the parts not included in the proposal.

- Lower price: Forgetting to add in the price of that part lowers your average ticket.

- Part run: If you don't discover the missing part until your crew is working, you may have to do a part run, adding extra labor.

- Job rollover: Leaving the job site for an extended period disrupts your crew's productivity and could lead to job rollover (unscheduled time the next day).

- Callback: If your team rushes to finish the job the next day, the system could be installed incorrectly and require a callback for repairs. How much can a callback set you back? Each time you have to send a service tech out for a callback, you're losing hundreds of dollars in revenue — the cost of the lost time he or she could have been out doing a profitable job.

These inaccuracies and delays are especially problematic during the busy season when your team works as quickly as possible to get everything done on time and within budget. It's the worst time to make mistakes because they are more likely to lead to expensive delays and dissatisfied customers.

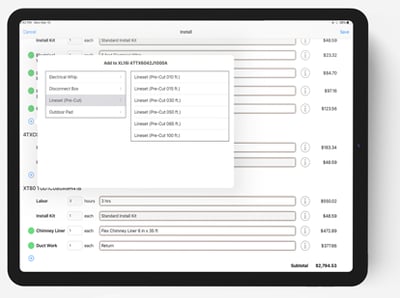

Solution: Based on the type of equipment installed, Install Manager Pro features the following item categories in the bill of materials:

Solution: Based on the type of equipment installed, Install Manager Pro features the following item categories in the bill of materials:

- Required or mandatory items: These are the must-have items your HVAC installation requires. For example, for a new AC system, you need to install a line set for the AC coil. This will automatically be populated in Install Manager Pro based on the minimum and maximum length and price specifications you set. Then your consultant can adjust the specifications as needed during the sales call.

- Recommended items: These are items that you should have but aren't necessary. For example, with a new AC unit, it's recommended that you include a new concrete pad or foundation. This will automatically be included in the bill of materials unless your consultant deselects it because the homeowner chooses to reuse the old pad.

- Optional items: Although not required, optional items are available to improve HVAC system performance. For example, a wind baffle for an outdoor unit can help with performance for certain wind conditions.

This three-tiered approach to creating a bill of materials is unique to Install Manager Pro. It removes the burden of remembering all the necessary details from your busy sales team by providing an accurate, immediate checklist at the point of sale.

- Accurate labor hour estimate

Challenge: Your installation crew may be used to working long days during the busy season. But if you don't estimate your labor hours accurately, their 10-hour workday may quickly spill over into an additional day. Unscheduled rollovers can quickly push your schedule back, which cuts into your profits, frustrates your customers, and erodes employee morale.

With hopes of winning the sale, your Comfort Consultant may be very optimistic about how much time is required to get the job done, thinking only one day is needed. If your crew rushes the job to try to finish in one day, this can lead to mistakes and callbacks.

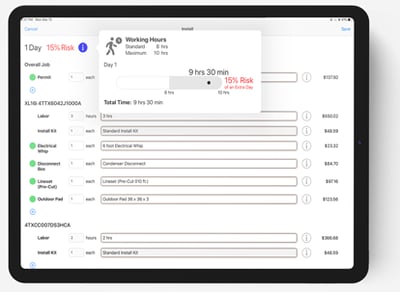

Solution: Install Manager Pro calculates accurate labor hour estimates based on the items selected in your bill of materials. All the guesswork and optimism in quoting are replaced by real-world estimates of how long it really takes to do each task. It assigns labor hours for each item, allowing you to specify the level of detail needed to calculate the correct labor hours. For example, you can specify line-set labor according to the length of the line set. The longer the line set, the more work that's required for installation.

Making these labor predictions early and accurately allows you to plan jobs better. For example, if you know a job is going to take 11 hours, you can ask the customer ahead of time if the crew can start early or stay late. You may also have the opportunity to send in a more experienced crew to get the job done more quickly. Implementing these strategies will help you prevent job rollovers and callbacks.

- Reliable risk management

Challenge: When it comes to planning HVAC installations, it can be difficult to predict the likelihood of rollovers, part runs, and callbacks — especially when complex tasks are involved. What if the job requires extensive ductwork or major electrical re-work? How much time will really be needed to complete the job? How can you predict if the work is likely to roll into a second day?

Solution: Install Manager Pro is the only tool on the market that assigns a level of risk to your labor hour estimations for each item in your bill of materials as well as any additional labor tasks.

Tasks that are less predictable carry more risk. For example, if your crew will need to deal with ladders and multilevel installs, there will be more risk associated with the labor hours than if the work was scheduled for a single-level home.

Install Manager Pro provides contractors with a set of risk defaults to start with. Over time, contractors can add to and improve these default risk values. When they identify areas of increased risk on the job, they can add these areas to the module. This helps drive continuous process improvement with the installations while building better collaboration and communication feedback between your sales and installation teams.

Improved professionalism and confidence

Install Manager Pro automatically builds a checklist for everything your Comfort Consultant needs to build a proposal accurately and efficiently. Arming your sales team with this information increases their knowledge and confidence when talking with customers and answering their questions. For example, the tool can quickly indicate that a consultant should start negotiating extra time for the job on the spot. This increases the overall professionalism of your staff and company, leading to more wins.

One of the biggest complaints that people have about contractors is that they struggle to get the work done on schedule. Install Manager Pro ensures that tasks are completed on time and indicates when there's a chance of job rollover. Work completed on time leads to better customers reviews. Better consumer reviews bring in more leads.

Cost savings

Install Manager Pro's exceptional accuracy and efficiency yield significant cost savings. For example, consider the amount of time that's required to draft an HVAC proposal. Install Manager Pro's automated process saves Comfort Consultants an hour preparing a single estimate. That allows your sales team to spend more time prospecting and visiting new customers — essential activities for driving new business.

The accuracy of the bill of materials and labor hour estimate can save your team from $100 to $1,000 per job since part runs, job rollovers, and callbacks are minimized.

Schedule a demo

Install Manager Pro is a module of Sales Builder Pro, our HVAC proposal solution. If you're already using the Sales Builder Pro Essential Package, upgrading to the Preferred or Premium Package will give you all the capabilities you need to ensure that every job is profitable. Request a demo to see Install Manager Pro in action.